In automotive manufacturing, precision isn't just important—it's everything. From the smallest details of a manufactured component to the overall safety and performance of a vehicle, the quality of the tools used in production can determine the outcome of the entire process. As the automotive industry moves towards more complex and lightweight designs, the need for cutting-edge technologies to ensure the perfection of every mold has never been greater, explains Jamie Buckingham, Director and General Manager of Machine Tool Products at Renishaw.

Advancing automotive industry standards

In mold design and manufacturing, precision is critical to ensuring the safety and performance of automotive components. The surface quality of a stamping tool, for example, is essential for producing vehicle components that meet the precise standards required by the industry. It can directly impact the functionality, quality, proper ejection from the mold, wear resistance, and surface aesthetics of the stamped component. Today, it is essential to produce these molds for the automotive industry using advanced technologies.

For more than 50 years, we at Renishaw have worked closely with our industry customers to solve key manufacturing challenges. We are renowned for designing, developing, and supplying process control and precision measurement solutions for manufacturing companies. Our range of non-contact tool gauges, for example, delivers industry-leading performance for tool measurement and broken tool detection.

Improving tool-to-tool accuracy

Automotive stamping processes can be complex, with multi-part parts and free-form surfaces. For stamping and painting applications, where multiple types of cutting tools are used to machine the surface of a single workpiece, it is essential that the transition from one tool to the next is absolutely precise. When switching between cutting tools, the length of these tools must be set with the utmost precision to avoid creating "steps" on the mold surface. Such an imperfection would then be reproduced on every component made from the defective mold, potentially compromising its performance.

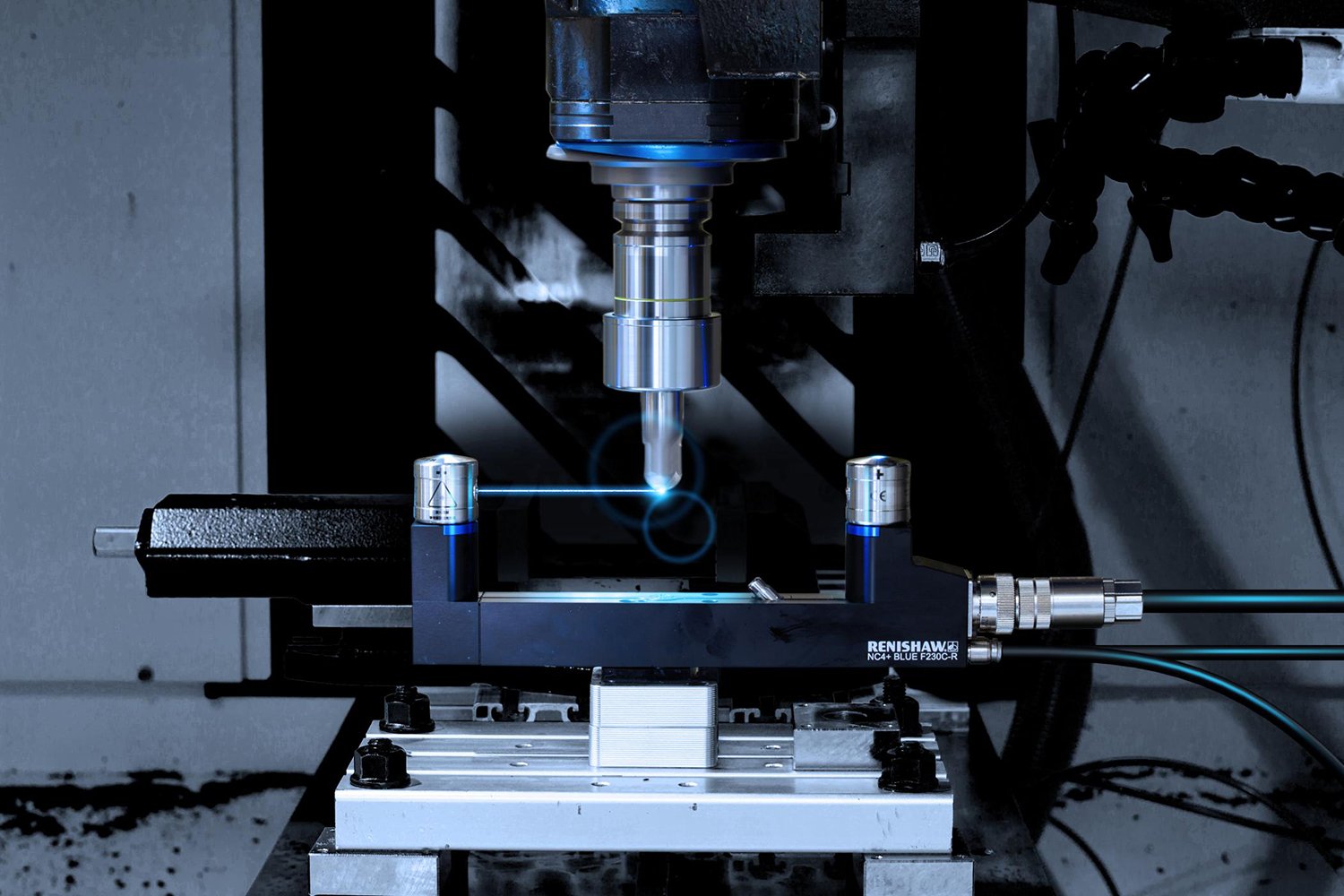

In CNC machining, cutting tool length errors can cause imperfections that result in machining features falling outside the required tolerances. Advanced tool setting systems can prevent these problems. For example, Renishaw's NC4+ Blue system features high-precision blue laser technology that provides reliable, non-contact measurement of cutting tools.

To further ensure consistent results, it also offers a built-in “air blast” for the quick and efficient removal of coolant and cutting debris from the cutting tool before measurement. To determine the cross-tool accuracy of length measurements made with our NC4+ Blue system, we use a dedicated cutting test based on an ISO standard (ISO 230-10 8.2.8.1.3). In a test conducted with a Makino D200Z 5-axis CNC machine tool, the NC4+ Blue measuring system was found to be accurate to within an incredibly small 2 microns.

Finding Tool Defects

Machining with a chipped cutting tool is another scenario that could negatively impact the surface quality of a molding tool. A surface finish with imperfections can affect the ease with which a component is removed from its mold. Components made of silicone or nylon, for example, may stick. Poor surface quality can also impede the flow of material within the mold, potentially requiring additional finishing and increasing the overall time required to produce the affected part.

The cutting tool defect may be just a few tens of microns in size, but it would still result in noticeable imperfections on a workpiece surface. Our NC4+ Blue system can measure tool length and diameter non-contactly and check for damaged cutting tools. It can measure very small parts to ensure excellent tool-to-tool accuracy, and it has a small footprint when inserted into the machine, so it takes up little space on its base.

Furthermore, the NC4+ Blue system offers an impressive suite of software cycles that can be used to detect even the smallest defects in cutting tools. This allows manufacturers to ensure high-quality surface finishes on their molds. These easy-to-use software cycles provide an intuitive way to measure a wide range of cutting tool imperfections that, if left unresolved, could result in poor surface finishes. The NC4+ Blue tool measurement system can perform high-speed checks to determine whether cutting tools are damaged or broken, and whether they have burrs or missing inserts. It can also examine the edge of cutting tools to detect chips as small as 30 microns in flutes. Additionally, the system can measure cutting tools made from a wide range of different materials and those that use internal coolant. At Renishaw, we understand that when it comes to automotive excellence, every micron counts. With over 50 years of experience, we guarantee the precision and reliability of every cutting tool and enable the automotive industry to achieve innovation, efficiency, and safety – one precise measurement at a time.